ZCY-G is a drive permanent magnet clean metal device, also could be used as rotational roller, could continual and automatic separate the ferromagnetism impurity which adulterate in non-magnetic material in the conveyer belt. To united this magnetic roller and hanging clean metal machine , could clean the impurity in the thick material layer .

This product is divided into two series , coincide with externality and install size of type DT 11 and DT 75 drive roller. For using conveniently , it was be extensively used in many industry , such as mining , electric , coal , port, construction materials, petrol-chemical , foodstuff etc .

Feature:

- The span of magnetic field in the surface of roller is big , this roller is conveniently used medium-sized magnetic field 150~250Mt and especial、strong magnetic field 300~400Mt

- This roller has Jarless magnetic field, could be used more than ten years , the magnetic road in core is provided a eight year long quality assurance

- Could be used as drive roller of conveyer belt, and separator.

- Compact structure, simple service , credible use

- it has a best effect in clean the impurity fe which in the bottom of the coal bed

|

|

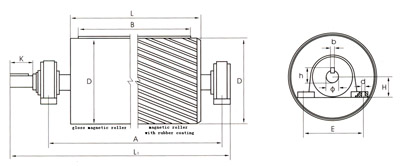

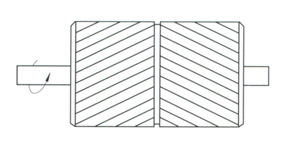

lambdoidal magnetic roller with rubber coating (left out shaft: Z) |

|

|

lambdoidal magnetic roller with rubber coating (right out shaft: Z) |

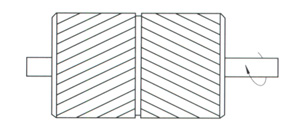

rhombic magnetic roller with rubber coated |

Guide to order:

- Choose roller in different diameter base in carrying capacity

- The type of the surface of the magnetic-roller :

A. Armor plate mill finish

B. cover with pastern ( three type : mill finish pastern., Lozenge pastern . herringbone pastern

- It is needed to record the axial when order the herringbone pastern

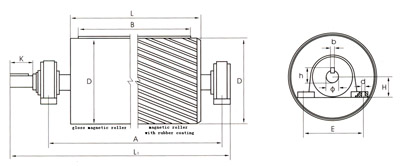

Technical Parameters of ZCY-G Permanent Magnetic Meparator Drive Roller

|

Type

ZCY-GB (cm) |

Roller Length

L |

Roller Diameter

D |

Shaft Head

Φ×K |

Key |

Bearing Base |

Bearing Model |

Overall Length

L1 |

Magnetic Force on roller surface (mT) |

Torque Permitted KN、m |

Weight

(Kg) |

|

b |

h |

A |

E |

H |

d |

gloss magnetic roller |

magnetic roller with rubber coating |

|

ZCY-G50 |

600 |

500 |

55×115 |

16 |

60 |

850 |

240 |

80 |

27 |

1312 |

1097 |

Regular P=150~250

Special

T=300~400 |

1.63 |

2.5 |

380 |

|

ZCY-G65-1 |

750 |

500 |

70×135 |

20 |

76 |

1000 |

350 |

120 |

27 |

1316 |

1280 |

2.12 |

3.26 |

580 |

|

ZCY-G65-2 |

630 |

2.96 |

4.54 |

800 |

|

ZCY-G80-1 |

950 |

500 |

70×135 |

20 |

76 |

1300 |

350 |

120 |

27 |

1316 |

1580 |

2.62 |

4.01 |

765 |

|

ZCY-G80-2 |

630 |

90×175 |

24 |

97 |

380 |

140 |

3520 |

1661 |

3.67 |

5.61 |

1090 |

|

ZCY-G80-3 |

800 |

5.59 |

8.55 |

1480 |

|

ZCY-G100-1 |

1150 |

630 |

90×135 |

24 |

97 |

1500 |

380 |

140 |

27 |

3520 |

1861 |

4.57 |

7.01 |

1285 |

|

ZCY-G100-2 |

800 |

110×215 |

32 |

119 |

440 |

160 |

34 |

3524 |

1945 |

6.96 |

10.68 |

1865 |

|

ZCY-G100-3 |

1000 |

130×225 |

36 |

140 |

480 |

180 |

3528 |

2020 |

|

17.75 |

2795 |

|

ZCY-G120-1 |

1400 |

630 |

110×215 |

32 |

119 |

1750 |

440 |

160 |

34 |

3524 |

2195 |

5.49 |

8.4 |

1610 |

|

ZCY-G120-2 |

800 |

8.37 |

12.81 |

2465 |

|

ZCY-G120-3 |

1000 |

130×225 |

36 |

140 |

480 |

180 |

3528 |

2270 |

|

21.3 |

3560 |

|

ZCY-G120-4 |

1250 |

150×275 |

40 |

161 |

540 |

200 |

3532 |

2305 |

|

30 |

5230 |

|

ZCY-G140-1 |

1600 |

800 |

110×215 |

32 |

119 |

2000 |

440 |

160 |

34 |

3524 |

2445 |

9.76 |

14.92 |

2865 |

|

ZCY-G140-2 |

1000 |

150×275 |

40 |

161 |

540 |

200 |

3532 |

2555 |

|

24.925 |

4405 |

|

ZCY-G140-3 |

1250 |

|

35.0 |

6005 |

|

ZCY-G140-4 |

1400 |

170×335 |

181 |

590 |

220 |

40 |

3536 |

2635 |

|

47.0 |

7535 |

|

|

|

|

|

lambdoidal magnetic roller with rubber coating (left out shaft: Z)

lambdoidal magnetic roller with rubber coating (left out shaft: Z)

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved