|

Samarium Cobalt holds its standard property in higher

maximum temperatures than neodymium,although its maximum strengh

is less. The cost of SmCo material is the most expensive,so SmCo

is recommended only when its performance is a high temperature environment

is a concern.

The characteristics of Samarium

Cobalt Magnet

*Very high magnetic properties with good stability.

*Superior resistance to high temperature,Curie temperature

of majority is over 800??

*Excellent corrosion resistance capability,no coating

is needed for surface protection.

Typical Magnetic Porperties of Samarium

Cobalt Materials

Properties of SmCo Permanent Magnet

|

Grade

|

Residual Flux Density

Br

|

Coercive Force Hcb

|

Intrinsic Coercive force Hcj

|

Max. energy product (BH)max

|

|

mT

|

kGs

|

kA/m

|

koe

|

kA/m

|

koe

|

kJ/m3

|

MGoe

|

|

SmCo-YX6

|

500~600

|

5.0~6.0

|

358 358

|

4.5~5.5

|

960 960

|

12.0 12.0

|

47~72

|

6~9

|

|

SmCo-YX10

|

600~700

|

6.0~7.0

|

438 438

|

5.5~6.5

|

1200 1200

|

15.0 15.0

|

64~88

|

8~11

|

|

SmCo-YX12

|

700~750

|

7.0~7.5

|

520 520

|

6.5~7.3

|

1591 1591

|

20.0 20.0

|

96~120

|

12~15

|

|

SmCo5-YX16

|

750~880

|

7.5~8.8

|

597 40 40

|

7.5 0.5 0.5

|

1591 1591

|

20.0 20.0

|

127 16 16

|

16 2 2

|

|

SmCo-YX16A

|

750~880

|

7.5~8.8

|

597 40 40

|

7.5 0.5 0.5

|

1989 1989

|

25.0 25.0

|

127 16 16

|

16 2 2

|

|

SmCo-YX16B

|

750~880

|

7.5~8.8

|

597 40 40

|

7.5 0.5 0.5

|

2386 2386

|

30.0 30.0

|

127 16 16

|

16 2 2

|

|

sm2co17-YX18

|

800~930

|

8.0~9.3

|

637 40 40

|

8.0 0.5 0.5

|

1194 1194

|

15.0 15.0

|

143 16 16

|

18 2 2

|

|

SmCo-YX18A

|

800~930

|

8.0~9.3

|

637 40 40

|

8.0 0.5 0.5

|

1591 1591

|

20.0 20.0

|

143 16 16

|

18 2 2

|

|

SmCo-YX18T

|

800~930

|

8.0~9.3

|

637 40 40

|

8.0 0.5 0.5

|

1591 1591

|

20.0 20.0

|

143 16 16

|

18 2 2

|

|

SmCo-YX18B

|

800~930

|

8.0~9.3

|

637 40 40

|

8.0 0.5 0.5

|

1989 1989

|

25.0 25.0

|

143 16 16

|

18 2 2

|

|

sm2co17-YX20

|

900~980

|

9.0~9.8

|

637 40 40

|

8.0 0.5 0.5

|

1432 1432

|

18.0 18.0

|

159 16 16

|

20 2 2

|

|

SmCo-YX20

|

900~950

|

9.0~9.5

|

670 670

|

8.5~9.2

|

1591 1591

|

20.0 20.0

|

159 16 16

|

20 2 2

|

|

SmCo-YX20A

|

900~980

|

9.0~9.8

|

637 40 40

|

8.0 0.5 0.5

|

1989 1989

|

25.0 25.0

|

159 16 16

|

20 2 2

|

|

SmCo-YX22

|

900~1030

|

9.0~10.3

|

653 40 40

|

8.2 0.5 0.5

|

1432 1432

|

18.0 18.0

|

175 16 16

|

22 2 2

|

|

SmCo-YX22A

|

900~1030

|

9.0~10.3

|

653 40 40

|

8.2 0.5 0.5

|

1989 1989

|

25.0 25.0

|

175 16 16

|

22 2 2

|

|

SmCo-YX24

|

950~1080

|

9.5~10.8

|

676 40 40

|

8.2 0.5 0.5

|

1432 1432

|

18.0 18.0

|

191 16 16

|

24 2 2

|

|

SmCo-YX24A

|

1000~1100

|

10.0~11.0

|

676 40 40

|

8.2 0.5 0.5

|

1989 1989

|

25.0 25.0

|

191 16 16

|

24 2 2

|

|

SmCo-YX26

|

1000~1130

|

10.0~11.3

|

357~516

|

4.5~6.5

|

413~556

|

5.0~7.0

|

207 16 16

|

26 2 2

|

|

YX26A

|

1000~1130

|

10.0~11.3

|

716 40 40

|

9.0 0.5 0.5

|

796 796

|

10.0 10.0

|

207 16 16

|

26 2 2

|

|

YX26B

|

1000~1130

|

10.0~11.3

|

716 40 40

|

9.0 0.5 0.5

|

1194 1194

|

15.0 15.0

|

207 16 16

|

26 2 2

|

|

YX26C

|

1000~1130

|

10.0~11.3

|

716 40 40

|

9.0 0.5 0.5

|

1591 1591

|

20.0 20.0

|

207 16 16

|

26 2 2

|

|

YX26D

|

1000~1080

|

10.0~10.8

|

732 732

|

9.0~10.5

|

2300 2300

|

30.0 30.0

|

207 16 16

|

26 2 2

|

|

SmCo-YX28

|

1060~1180

|

10.6~11.8

|

357~516

|

4.5~6.5

|

413~556

|

5.0~7.0

|

223 16 16

|

28 2 2

|

|

SmCo-YX28A

|

1060~1180

|

10.6~11.8

|

763 40 40

|

9.6 0.5 0.5

|

796 796

|

10.0 10.0

|

223 16 16

|

28 2 2

|

|

SmCo-YX28B

|

1050~1150

|

10.5~11.5

|

750 750

|

9.4~9.8

|

960 960

|

12.0 12.0

|

223 16 16

|

28 2 2

|

|

SmCo-YX28C

|

1060~1180

|

10.6~11.8

|

763 40 40

|

9.6 0.5 0.5

|

1194 1194

|

15.0 15.0

|

223 16 16

|

28 2 2

|

|

SmCo-YX30

|

1100~1200

|

11.0~12.0

|

438~597

|

5.5~6.5

|

454~597

|

5.7~7.5

|

238 16 16

|

30 2 2

|

|

SmCo-YX30A

|

1100~1200

|

11.0~12.0

|

560 560

|

7.0~8.5

|

716 716

|

12.0 12.0

|

238 16 16

|

30 2 2

|

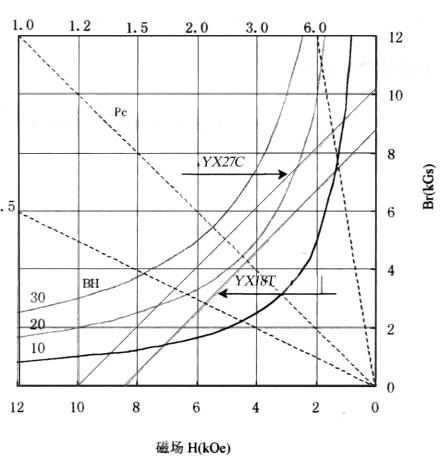

Characteristics & application of SmCo permanent

magnet

Typical Characteristic Curve

for SmCo permanent magnet

Characteristics & application

of SmCo permanent magnet

1.SmCo permanent magnet has high magnetic

energy product andhigh cercive force. Its properties are better

than Alnico,ferrite permanent magnet. Its max. energy product is

up to 239kJ/m3(30MGOe), which is three times of that of Alnico8

permanent magnet, eight times of that of ferrite permanent magnet

(Y40). So the permanent magnetic component made from SmCo material

is small, light and stable in property. It is widely applied to

electro acoustic& telecommunication apparatus, electric motors,

measure meters, peg-top,electronic watch,microwave apparatus, magnetic

mechanism, sensor and other static or dynamic magnetic routes.

2.The curie temp. of the SmCopermanent

magnet is high and its temp. Coeff.is low. So it is suitable for

use at 300, high temp.

3.SmCo permanent magnet is hear and

bristle. Its rigidity strength, tensile strength and press strength

are low. So it is not suitable for framework.

4.The main ingredient of SmCo permanent

magnet is metal cobalt(Co Y99.95%).

So its price is high. Y99.95%).

So its price is high.

Reference points for application design of permanent

magnet

1.What we stated herein are typical

grades of SmCo permanent magnet only. We could meet your requirements

for various magnetic properties too.

2.For application of permanent magnet

at high temp., you need consider the following two important parameters:

recoil temp. coeff( )

and intrinsic coercive force(Hcj). Recoil temp. coeff. is a parameter

to measure the performance of the permanent magnet with the variation

of the temp. When the temp come back to the initial value, the magnetic

properties of the permanent magnet will reversibly return to the

initial condition too. More smaller the temperature coefficient

is, more lower the magnetic properties are. In the meantime, with

the variation of the temperature, the magnetic properties of permanent

magnet can change irreversibly. This is called irreversible loss.

The irreversible loss descends with the increase of the intrinsic

coercive force. )

and intrinsic coercive force(Hcj). Recoil temp. coeff. is a parameter

to measure the performance of the permanent magnet with the variation

of the temp. When the temp come back to the initial value, the magnetic

properties of the permanent magnet will reversibly return to the

initial condition too. More smaller the temperature coefficient

is, more lower the magnetic properties are. In the meantime, with

the variation of the temperature, the magnetic properties of permanent

magnet can change irreversibly. This is called irreversible loss.

The irreversible loss descends with the increase of the intrinsic

coercive force.

3.The appropriate dimensions of he

permanent magnet should be taken into account for the application

design. Generally speaking, the demagnetization curve of SmCo permanent

magnet is close to a straight line and the difference value between

Residual Flux Density Br & coercive force Hcb is relatively

small. So we should choose the working point (Pc value) around the

Max. energy product, i.e. (BH)max. Thus we could utilize the magnetic

energy fully and save the cost greatly. Design reference: 0.5 Pc Pc 1. 1.

4.SmCo permanent magnet is a functional

material. It is unsuitable for structure part design. So the usual

requirement to the tolerance of the dimensions for structure part

is not applicable to it. For the detailed tolerance design, please

refer to "permanent magnet supply illustration".

5.SmCo permanent magnet has strong

anticorruption function. So it needn't similar surface treatment

as that of NdFeB magnet. For the surface protect of SmCo permanent

magnet, please turn to "surface protect and protect coating

of permanent magnet". The coating will add to the cost in turn.

l Inspection standard

for permanent magnet

l Purchasing Guide

l Permanent magnet

supply direction

l Surface protection

and surface coating for the permanent magnet

l Quality warranty

l Safety principle

for manual operation of permanent magnet

|