|

Alnico

materials (composed predominantly of aluminum,nickel,and cobalt

with minor amounts of other elements including titanium and copper)

permit design latitudes providing high indications,high energies

and relatively high coercivities.Alnico magnets are characterized

by excellent temperature stability and good resistance to demagnetization

from vibration and shock.Alnico magnets offer the best temperature

characteristics of any standard production magnet material available,.They

can be used for continuous duty applications where temperature extremes

up to 930F can be expected. Alnico

materials (composed predominantly of aluminum,nickel,and cobalt

with minor amounts of other elements including titanium and copper)

permit design latitudes providing high indications,high energies

and relatively high coercivities.Alnico magnets are characterized

by excellent temperature stability and good resistance to demagnetization

from vibration and shock.Alnico magnets offer the best temperature

characteristics of any standard production magnet material available,.They

can be used for continuous duty applications where temperature extremes

up to 930F can be expected.

Alnico magnetsl are

manufactured through either a casting or sintering process. Alnico

magnet is very hard and brittle.Machining or drilling can not therefore

be accomplished by ordinary methods.Holes are usually cored in at

the foundry.Magnets are cast or sintered as closely as possible

to required sized so that abrasive grinding to finish dimensions

and tolerances is minimized

Specialized

casting techniques used to achieve

the unique crystalline grain orientation found in the Alnico 5 and

8 grades.These anisotropic grades are designed to produce high magnetic output in a specified

direction.Orientation is achieved during heat treatment, by cooling

the casting

from 2000F at a controlled

rate within a magnetic field which conforms to the preferred direction

of magnetization. Alnico 5 and Alnico 8 are anisotropic and exhibit a preferred

direction of orientation,Magnetic orientation should be specified

on your drawing when you send an order to us.

Cast

Alnico 5

is the most commonly used of all the cast Alnico's .It combines

high indications with a high energy product of 5 MGOe or more and

is used extensively in rotation machinery, communications, meters

and instruments, sensing devices and holding applications. The higher

resistance to demagnetization(coercive force) of Alnico 8,cobalt content to 35%,allows this material to function well

for short lengths or for length to diameter ratios of less than

2 to 1.

Sintered

Alnico materials offer slightly lower magnetic properties but butter mechanical characteristics

than the cast Alnico materials.Sintered Alnico magnets are most suitable

in small sizes(less than 1 oz.)in this process. The desired mix

of metal powder is pressed to shape and size in a die,then sintered

at 2300 F in a hydrogen atmosphere.The sintering process is well

suited to large volume production,and results in parts which are

structurally stronger than cast magnets.Relatively close tolerances

can be achieved without grinding.

The

Characteristics of Alnico Magnet:

*Small changes in

magnetic properties to temperature effects

*Maximum working temperature

can be as high as 450oC~550oC.

*Low coercive force.

*Strong corrosion

resistance capability,no coating needed for surface protection.

Typical Applications

for Alnico magnet:

Widely used applications

such as instruments and meters which require very stable

temperature properties.

Electronic ignition

systems,watt bour meters,volt-amp meters.medical instruments,industrial

motors,magnetic reed switches,generators,hand tools,vending machines.

Typical

Magnetic Performance Range for Cast Alnico Magnet

|

Grade

|

Br

|

Hc

|

(BH)max

|

MMPA Equivalent

|

Temp. Coefficient

|

Tc

|

Tw

|

|

mT

|

KGs

|

KA/M

|

Oe

|

KJ/m3

|

MGOe

|

%/

|

|

|

|

LN9

|

690

|

6.9

|

37

|

470

|

10.0

|

1.25

|

Alnico1

|

-0.03

|

760

|

500

|

|

LNG12

|

700

|

7

|

40

|

500

|

12.0

|

1.50

|

Alnico2

|

-0.03

|

810

|

500

|

|

*LNG13

|

680

|

6.8

|

48

|

600

|

12.0

|

1.50

|

Alnico2

|

-0.03

|

810

|

500

|

|

*LN10

|

600

|

6

|

40

|

500

|

10

|

1.2

|

Alnico3

|

-0.03

|

760

|

500

|

|

LNGT18

|

580

|

5.8

|

90

|

1130

|

18.0

|

2.20

|

[l.Alnico7]

|

-0.03

|

860

|

500

|

|

LNG16

|

800

|

8

|

53

|

660

|

16.0

|

2.00

|

[Alnico4]

|

-0.02

|

850

|

500

|

|

LNG34

|

1180

|

11.8

|

44

|

550

|

35.0

|

4.30

|

[Alnico5C]

|

-0.02

|

890

|

500

|

|

LNG37

|

1180

|

11.8

|

48

|

600

|

37.0

|

4.65

|

Alnico 5

|

-0.02

|

890

|

500

|

|

LNG40

|

1220

|

12.2

|

48

|

600

|

40.0

|

5.00

|

-0.02

|

890

|

500

|

|

LNG44

|

1220

|

12.2

|

52

|

650

|

44.0

|

5.50

|

Alnico 5 DG

|

-0.02

|

890

|

500

|

|

LNG 52

|

1250

|

12.5

|

55

|

690

|

52.0

|

6.50

|

Alnico 5-7

|

-0.02

|

890

|

550

|

|

LNG60

|

1300

|

13

|

56

|

700

|

60.0

|

7.50

|

Alnico 6

|

-0.02

|

890

|

500

|

|

LNGT28

|

1050

|

10.50

|

56

|

700

|

28.0

|

3.50

|

Alnico 8

|

-0.02

|

860

|

550

|

|

LNGT32

|

800

|

8

|

104

|

1300

|

34

|

4.25

|

-0.03

|

860

|

550

|

|

LNGT38

|

820

|

8.2

|

110

|

1380

|

38.0

|

4.75

|

-0.03

|

860

|

550

|

|

LNGT44

|

880

|

8.8

|

120

|

1500

|

44.0

|

5.50

|

-0.03

|

860

|

550

|

|

LNGT60

|

900

|

9

|

110

|

1380

|

60

|

7.5

|

Alnico 9

|

-0.03

|

860

|

550

|

|

LNGT72

|

1050

|

10.5

|

112

|

1410

|

72

|

9

|

|

-0.03

|

860

|

550

|

|

LNGT36J

|

700

|

7

|

140

|

1750

|

36

|

4.5

|

Alnico 8HC

|

-0.03

|

860

|

550

|

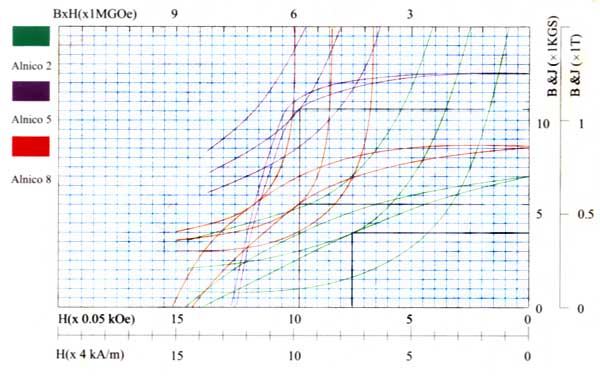

Demagnetization Curve of Cast Alnico

Magnet

l Inspection standard

for permanent magnet

l Purchasing Guide

l Permanent magnet

supply direction

l Surface protection

and surface coating for the permanent magnet

l Quality warranty

l Safety principle

for manual operation of permanent magnet

|